Team Global Express, formerly known as TOLL Logistics Company, is the third largest company in Australia's logistics industry. The company operates warehouses in all Australian states and processes roughly 10,000 pickup and delivery orders daily from a single warehouse in NSW/Sydney. A custom-built web-based application manages all transportation orders.

Inbound data import and verification

The 1C:Enterprise platform, in conjunction with the logistics module, developed by 1Ci Partner IronLogic, was introduced to automatically distribute freight to drivers daily. The solution was designed on the 1C:Enterprise BSP configuration with automatic import of orders to the 1C:Enterprise platform via FTP connection.

In this article, we will share some details on the new workflow, highlighting how the integration of the 1C:Enterprise platform has optimized the allocation of resources, scheduling, and streamlined the process of order management and distribution.

Inbound Data Import and Verification

The new workflow begins with an automatic data import into the 1C platform. Key steps include:

-

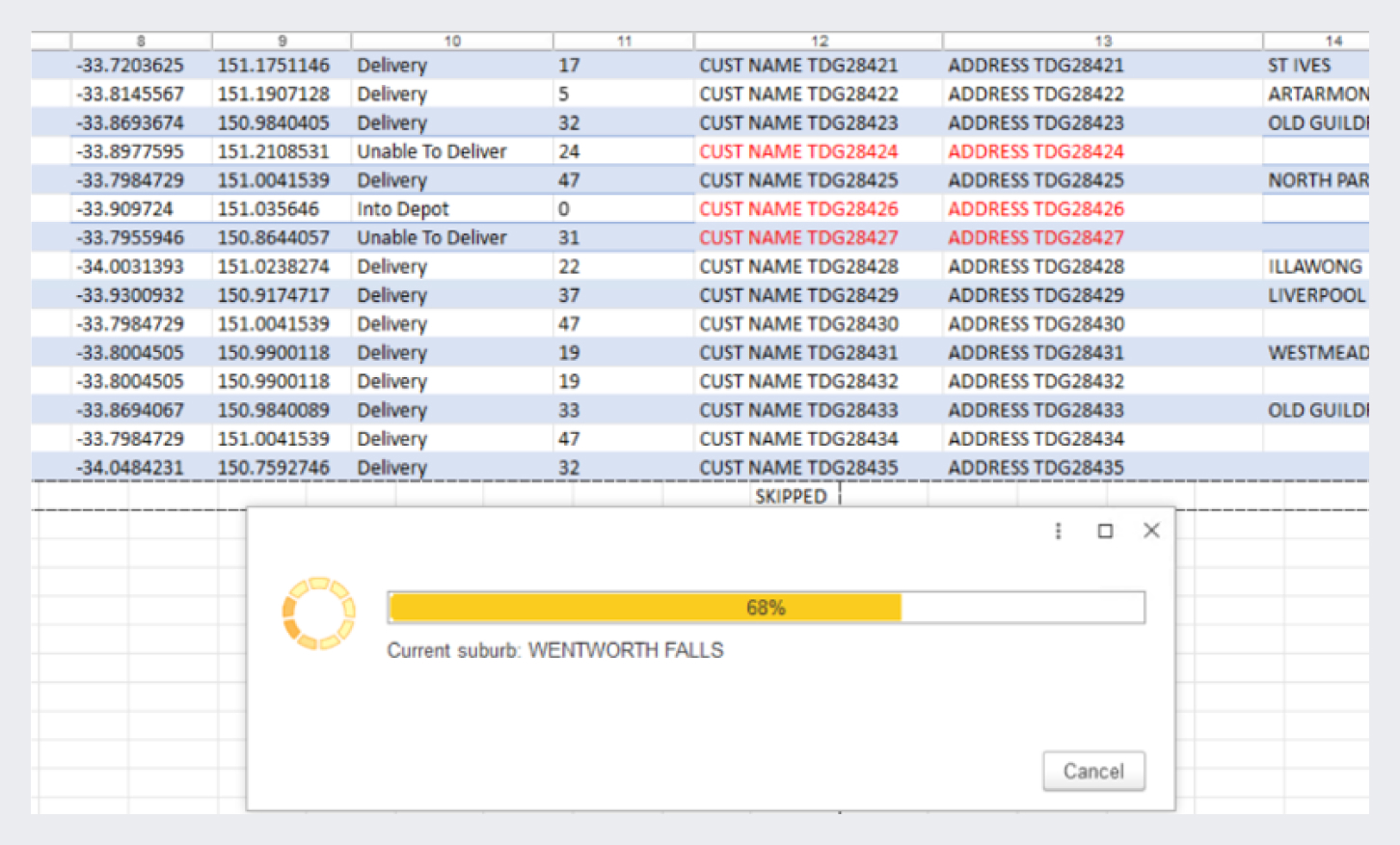

Data Verification: Data, including GPS coordinates and addresses, is crosschecked against the original information.

-

Continuous Monitoring: The 1C platform continuously monitors a designated FTP folder for new files, automatically processing and verifying the data.

-

Discrepancy Flagging: Discrepancies in GPS coordinates beyond a set threshold are flagged for manual verification. All coordinates are viewable on a map within the platform.

The Data Import Process

The data import process

After resolving any issues, the corrected data is imported into 1C:Enterprise. This data includes:

-

Order Timeframes: Specific deadlines for each order.

-

Special Requirements: Details such as refrigeration or handling of dangerous goods.

This ensures the proper assignment of vehicles and drivers to meet each order's specific needs.

Orders clusterization

To manage the high volume of freight, the system employs AI to allocate orders into different clusters based on various factors, including:

-

Past delivery and pickup times

-

Order density in various suburbs

During the import process, two instances are created in 1C:Enterprise:

1. Transportation Order: Contains all the order information from the Excel file.

2. Information Register: Records key details such as:

-

Delivery/pickup dates

-

Suburbs

-

Total weight

-

Number of items

-

Calculated service time needed for each suburb

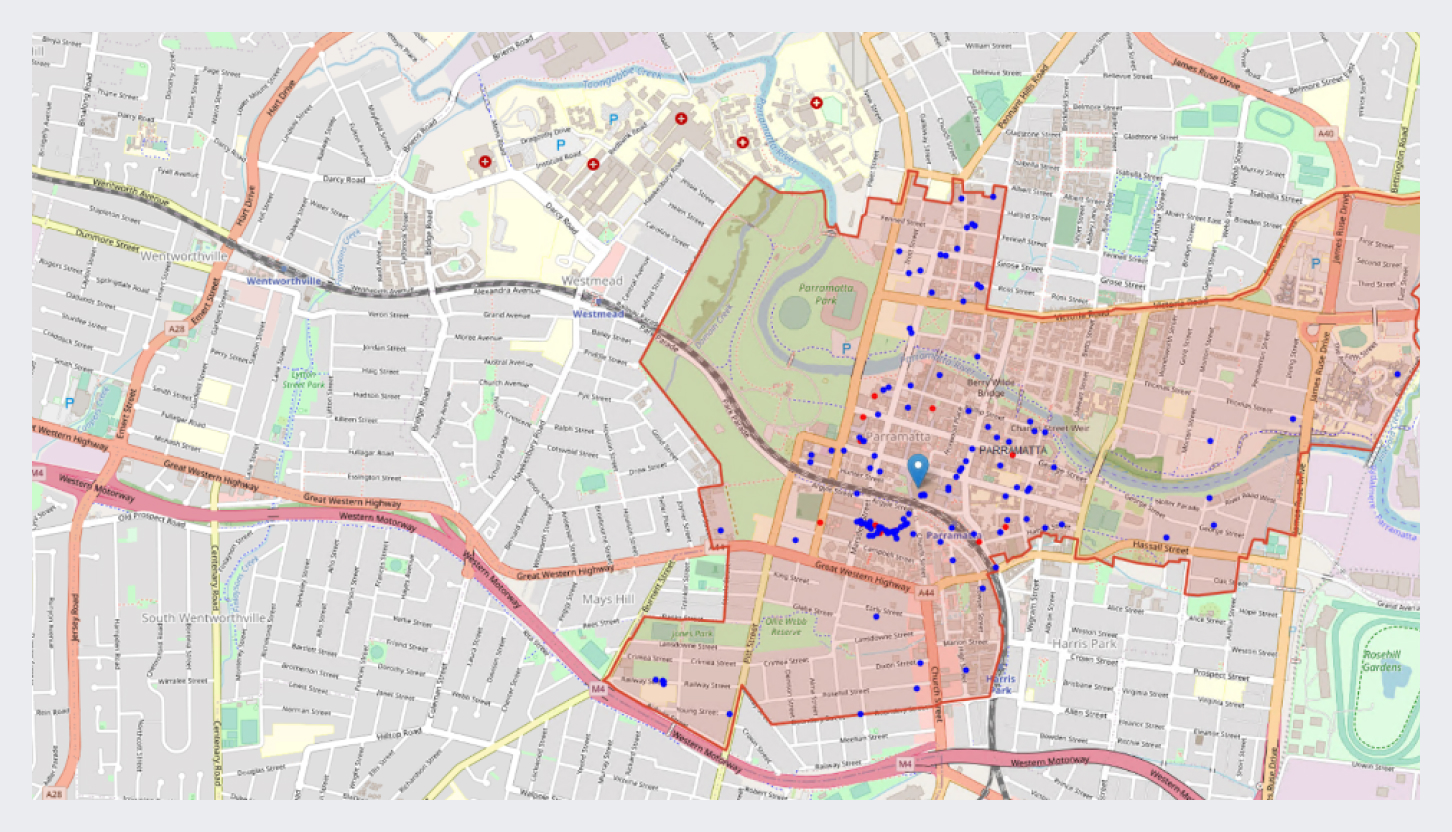

This register can visually represent pickups and deliveries on a map, using:

-

Red points for pickups

-

Blue points for deliveries

This map shows deliveries and pickups within a suburb for the day. Red points indicate pickups, and blue points indicate deliveries.

This map shows deliveries and pickups within a suburb for the day. Red points indicate pickups, and blue points indicate deliveries.

The cluster calculation process automatically groups zones by considering:

-

Real driving times between central locations

-

The number of consignments in each suburb

Instead of focusing on exact delivery and pickup points, the system consolidates consignments within delivery suburbs, streamlining calculations and significantly reducing the number of coordinates required.

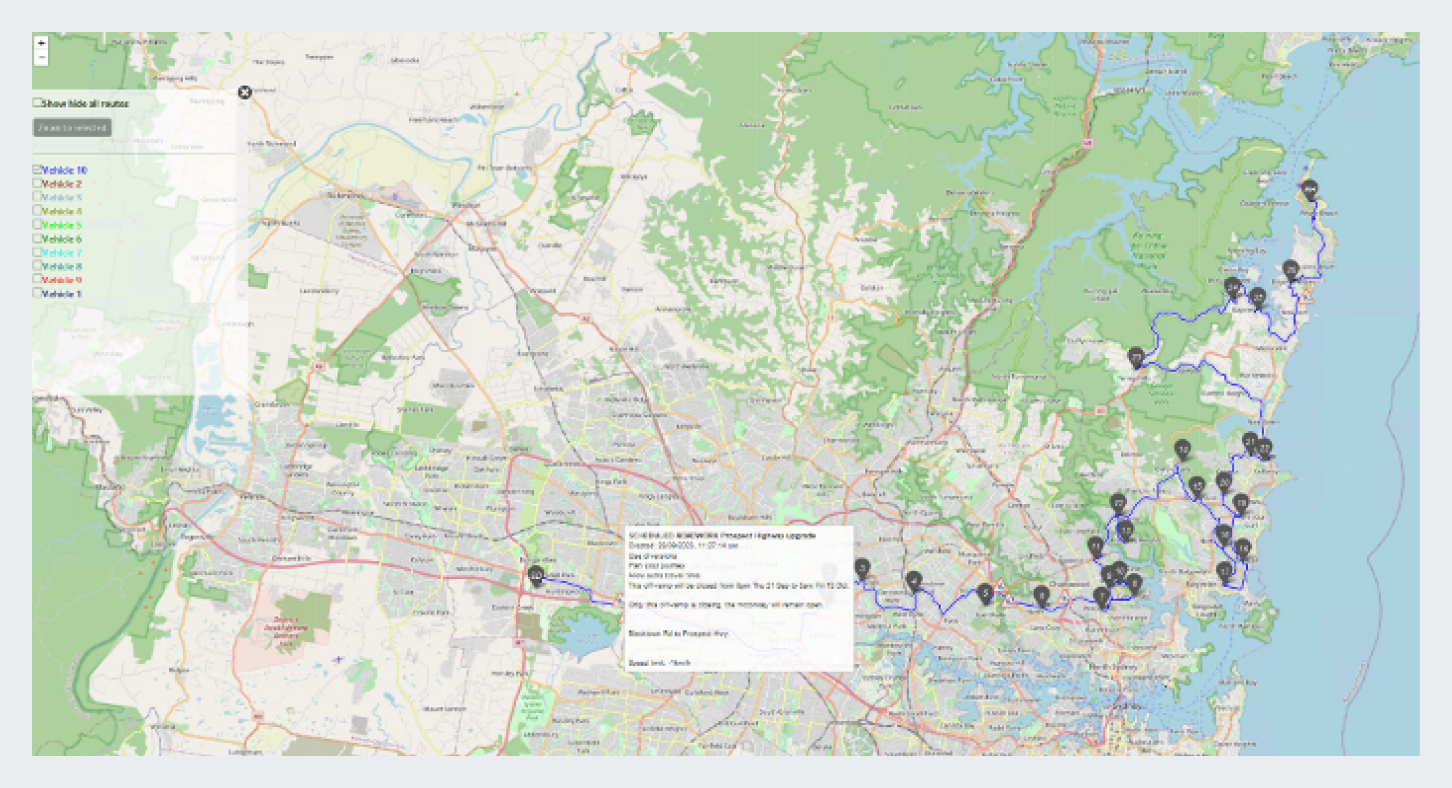

Schedule and Route Calculation

The system begins by performing a rough calculation of drivers' schedules across various areas, estimating the time drivers will spend in each suburb for deliveries and pickups. Once the approximate delivery/pickup times are determined, the system automatically generates precise routes for drivers.

Transportation Order Document

A 'Transportation Order' document is created containing all relevant information, which can also be viewed on a map. Routes can be calculated by:

-

Selecting multiple orders in "Transportation Orders"

-

Processing large datasets in two stages:

-

Grouping orders into a central point with approximate service times

-

Performing exact route calculations

The system allows for the inclusion of various constraints, such as:

-

Order timeframes

-

Drivers' breaks

-

Vehicle-specific requirements

-

Vehicle capacity limits

Drivers' working hours and breaks can be easily configured using a Gantt-chart view, where adjustments are made by dragging the time bar or through the driver's menu.

Route Details

Route details are represented on the map.

The final solution includes a summary of each route, with detailed views available in:

-

Table format

-

Geographical map

-

Gantt chart visualization

Orders are distributed to drivers' mobile devices (iOS and Android), with automatic feedback from drivers that includes:

-

Proof of delivery images

-

Signatures

-

Comments

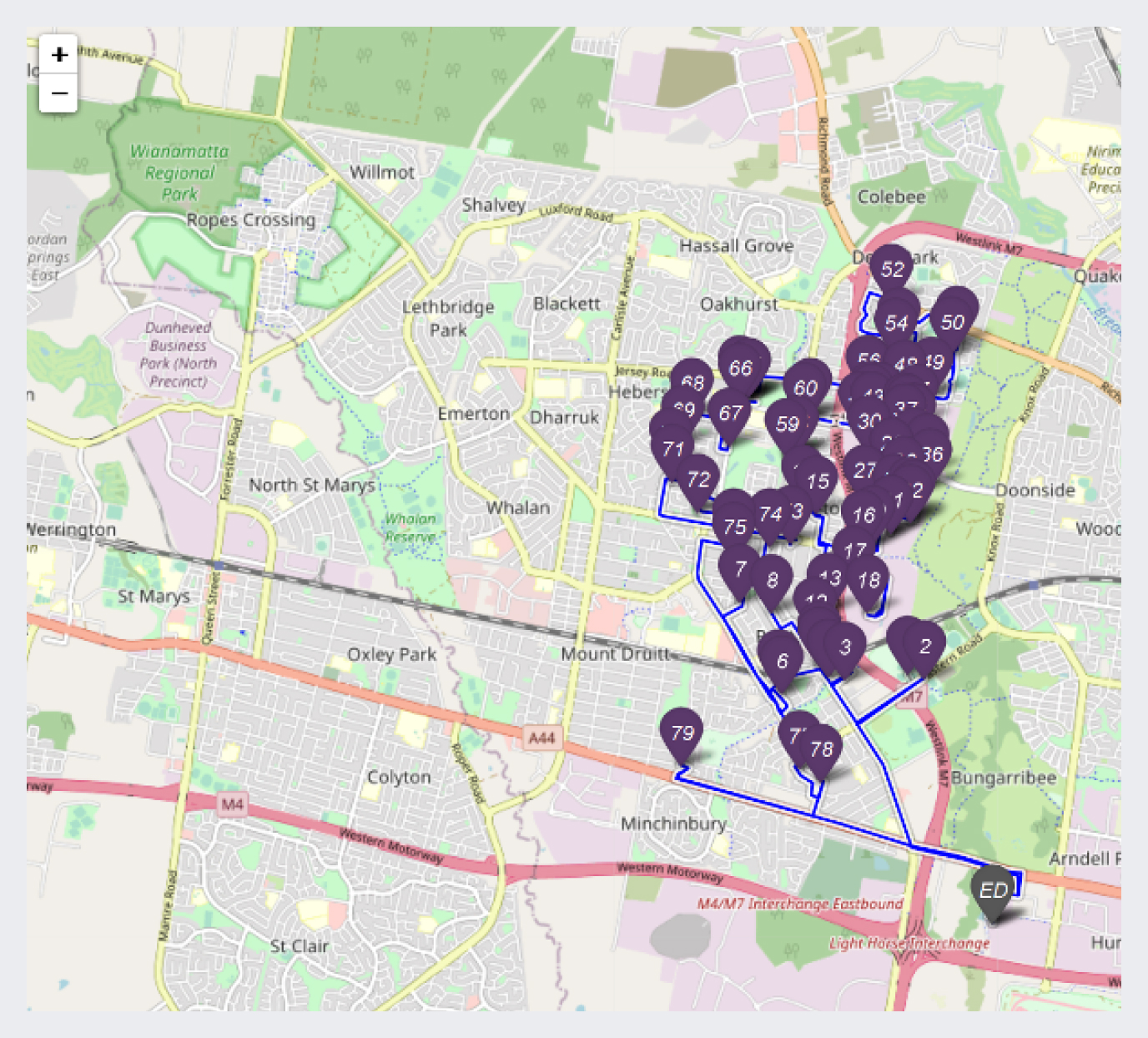

An example of a route within a specific manifest

The system organizes orders into manifests, which are groups of orders and suburbs that drivers need to visit. These manifests can be viewed in a dedicated Manifest form window, with both the list of orders and suburbs available, as well as a visual representation on a map.

Conclusion

To sum up, the integration of 1C:Enterprise into Team Global Express logistics operations has significantly enhanced the efficiency and accuracy of order management and distribution.

Through automated data import, intelligent order clusterization, and precise schedule and route calculation, the system has streamlined the entire logistics process from order receipt to final delivery. The ability to visualize routes, monitor real-time progress, and incorporate driver feedback has further optimized the workflow, ensuring that Team Global Express can meet the complex demands of the logistics industry.