This article covers frequently asked questions about operations with items, which can be measured both in pieces and in metric units: tons, cubic meters, and so on. It provides several examples and explanations of the necessary system settings.

Issues

To better understand the issue of operating with metric units of measure, we will consider several cases.

Suppose our company produces metal structures, and our main material is rolled metal. For example, steel sheet.

Rolled metal vendors generally use weight units of measure. Although sheets are supplied in pieces (like sheets of a certain brand of metal with a certain thickness, length, and width), but kilograms, or most likely tons, will appear in the vendor price list. Tons will be used to order materials from vendors and in delivery documents.

This causes the following issues: when receiving goods to the warehouse and during the inventory count, it is more convenient for us to use sheets (pieces). We will also have to transfer the materials to production in sheets.

You can assume that tons must somehow be converted into pieces: one sheet has a specified weight according to GOST (state standard), and we can convert tons into sheets and back. This task seems to be solved by creating two units of measure in the item card (piece (sheet) and ton) with specifying the conversion ratio of pieces into tons and back.

This might be true, but there is one issue: metal rolling is not precision production and there might be deviations. The weight of a particular sheet may deviate from the given standard by a percentage. This is even acceptable according to GOST: the manufactured product parameters may vary within certain limits for certain types of rolled products.

So, we need to convert tons into sheets not by direct recalculation, but taking into account rounding up to the nearest integer number of pieces (sheets) within a given deviation value. The task becomes more complex and raises many questions, mainly how to organize everything correctly in 1C:ERP.

An almost similar situation arises for lumber (like boards and bars): the materials and prices are supplied in cubic meters, but it is more convenient to transfer it to production in boards (pieces).

Even more interesting examples are found in construction. For example, insulation materials (slabs of stone wool) are sold in cubic meters, then delivered in packages containing several slabs. But, when planning the consumption of this material for facade insulation, it is more convenient to consider facade area, that is, plan the consumption in square meters. That gives us three units of measure to work with.

Metal rolling case

Now we will analyze how to correctly set up the system to account for rolled metal products.

Let's say we need to create the Hot rolled sheet /1.5 /1000.0 /2000.0 / St3sp /GOST 16523 / mill edge item in the system.

These numbers mean:

-

1.5. Thickness of the sheet in millimeters.

-

1000.0. Width of the sheet in millimeters.

-

2000.0. Length of the sheet in millimeters.

-

St3sp. Steel grade.

-

GOST 16523. Standard requirements according to which this sheet was produced.

-

Mill edge. Sheets with such edge are not cut; they have a natural slightly uneven edge shape obtained after rolling the workpiece through a rolling mill.

A ton of this material costs 49 thousand rubles.

The weight of one sheet is 23.54 kg.

Let us start with a stock UOM of this item. In 1C:ERP, a stock UOM is a unit of warehouse accounting. It will be a piece (sheet) in our case. The reasons are as follows:

-

Although the goods appear in the delivery documents in tons, it is more convenient to store them in pieces. The sheets are easier to count, and most production warehouses are not equipped with scales to measure the weight of the arrived goods.

-

It is more convenient to perform an inventory count of such goods in sheets (pieces). It is quite difficult to imagine someone in a large warehouse drag sheets onto scales (even if they exist) to weigh the actual stock (we are not talking about scrap metal now).

-

It is also more convenient to transfer metal to production in sheets. In most cases, the warehouse is not a metal cutting site (otherwise it is a production business unit and no longer a warehouse), so it operates with whole sheets.

Theoretically, it is possible to set tons (or kilograms) as a storage unit, and this is even familiar to many old school warehouse keepers. This will lead to the following options with their disadvantages:

-

Warehouse keepers should know a conversion table from pieces to tons and back to quickly convert one into another when they need to issue goods from the warehouse, because they actually use sheets. The range of rolled metal products is large, so they will have to learn a lot.

-

You can provide warehouse keepers with a conversion table on paper and a calculator to recalculate these values, but this is a strange situation for a company with an accounting automation system.

-

You can create another unit of measure in packaging units, call it a "sheet", and specify the conversion ratio in tons there. But this contradicts the logic of the Packaging units catalog: we do not pack metal items in sheets in the warehouse. Sheets are sheets, not a packaging unit. There is another disadvantage: the conversion ratio from sheets to tons will not allow us to issue goods in sheets if we have fewer tons than specified for one sheet in the conversion ratio (within GOST). You will have to check how much metal you have in weight, or issue it by weight (keeping in mind that it is a whole sheet), or specify a fractional part of the sheet in documents so that it corresponds to the remaining weight. This will sooner or later bring us back to the calculator and the paper table with the scales on the warehouse keeper's table.

Keeping all these disadvantages in mind, we will use sheets (pieces) as a stock UOM. The next question is what to do with tons in which the goods are delivered by the vendor.

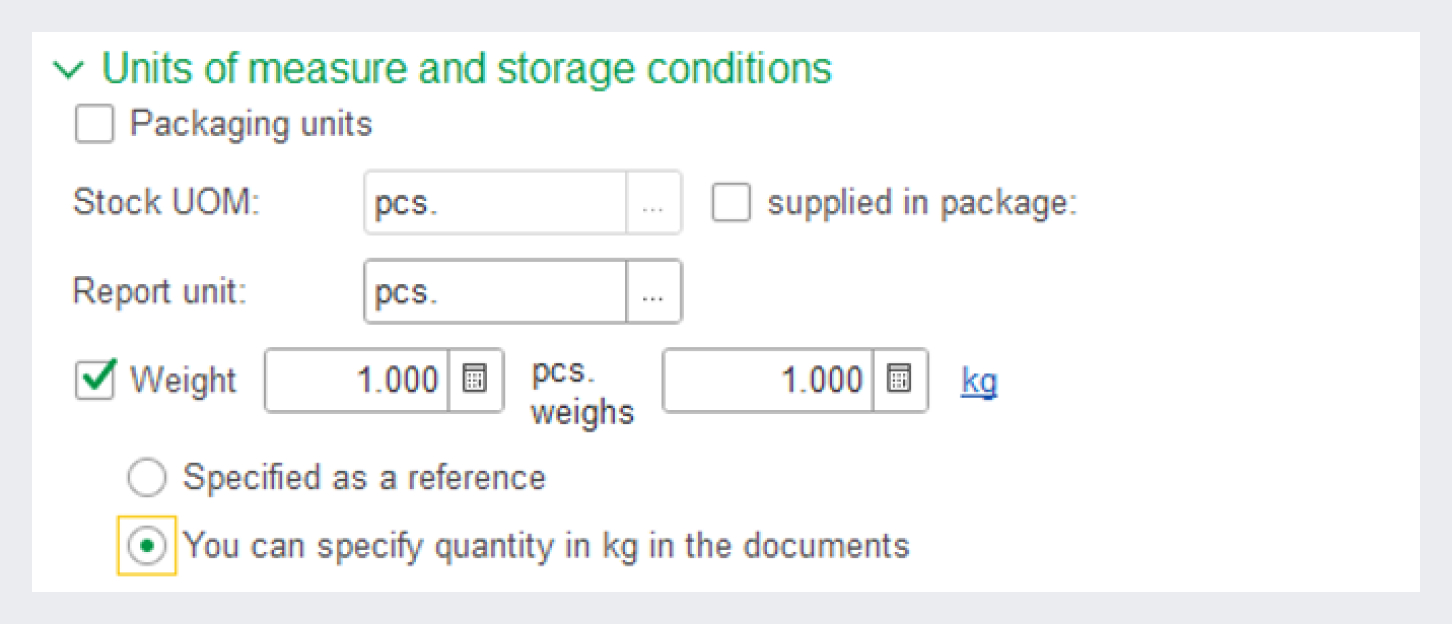

For that, there is the Weight attribute in the item card:

Specifying the item weight

By enabling this attribute, we can specify the conversion ratio from pieces (sheets) to weight (kilograms). The system will then recalculate kilograms to tons.

Do not forget to select You can specify quantity in kg in documents for the Weight attribute for the system to automatically recalculate sheets into kilograms/tons and vice versa.

To see stock balances not only in sheets, but also in tons, we can use the report UOM (as shown in the same figure), and specify how many sheets one ton of metal contains. After that, we will be able to get information in both sheets and tons in reports.

Let us get back to the rounding issue. Assume that we received 2.35 tons of metal from the vendor. Most likely, we received about one hundred sheets of metal (2.35 t / 100 = 23.5 kg) with a deviation from 23.54 kg (weight of one sheet) according to GOST. At first glance, we cannot register such operation in the system: 2.35 t / 23.54 kg = 99.83 sheets. The goods are stored in pieces, we can only accept it to the warehouse in integers.

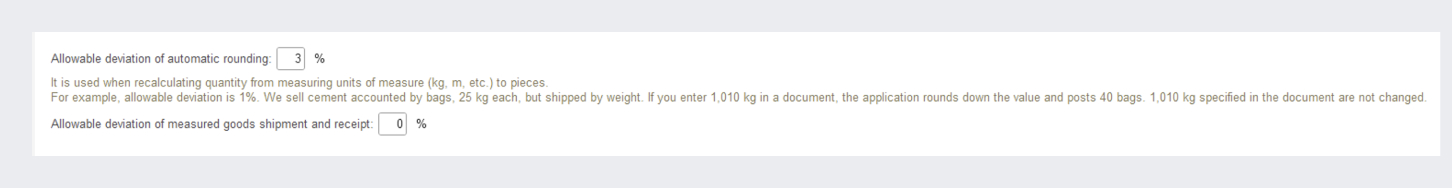

In this case, we can use a rounding feature, which is enabled in Master data and settings – Items – Units of measure.

Setting up allowable deviation

After setting up the percentage of allowable deviation, the system behaves as follows:

1. We specify 2.35 tons in the receipt documents.

2. The system gets the number of sheets: 2.35 t / 23.54 kg = 99.83 sheets.

3. Calculates the nearest integer number of sheets: 100 sheets.

4. Calculates the difference between a fractional and an integer number of sheets: 100 - 99.83 = 0.17.

5. Calculates the deviation percentage: (0.17 sheets / 100 sheets) * 100 = 0.17%. This is less than the specified percentage, so we can specify 100 sheets in documents.

We do not see all these calculations. The system calculates everything automatically. We also do not see 100 sheets to which the system rounded up our 2.35 tons: they are stored inside the document row in the hidden "Quantity in stock UOM" field, while the user only sees the original 2.35 tons.

Here is one more compromise option when you need to operate with two units of measure. For example, in meat processing, you need to operate with products both in pieces and in weight.

The actions are the same:

-

For a sausage item, we specify a piece as a stock UOM.

-

Enable the Weight attribute in documents.

-

Then we can produce sausages in kilograms/tons, ship them in pieces, and so on.

However, one needs to understand that this is not a full-fledged accounting in two units. The system accounts for goods in pieces and recalculates them into weight only if necessary using the conversion ratio specified in the item card. But, as practice shows, a full-fledged accounting in two units of measure is extremely rarely needed. For example, in wholesale trade and transportation of gasoline, the same amount of fuel can occupy a different volume depending on the ambient temperature, and these are significant deviations, sometimes tens of percent.

Lumber case

Suppose our company buys lumber to produce packaging (pallets). Such materials are sold in cubic meters (volume). It is better to keep warehouse records for them in boards (pieces), and, as for production, consumption standards are likely to be calculated in meters (number of meters per pallet).

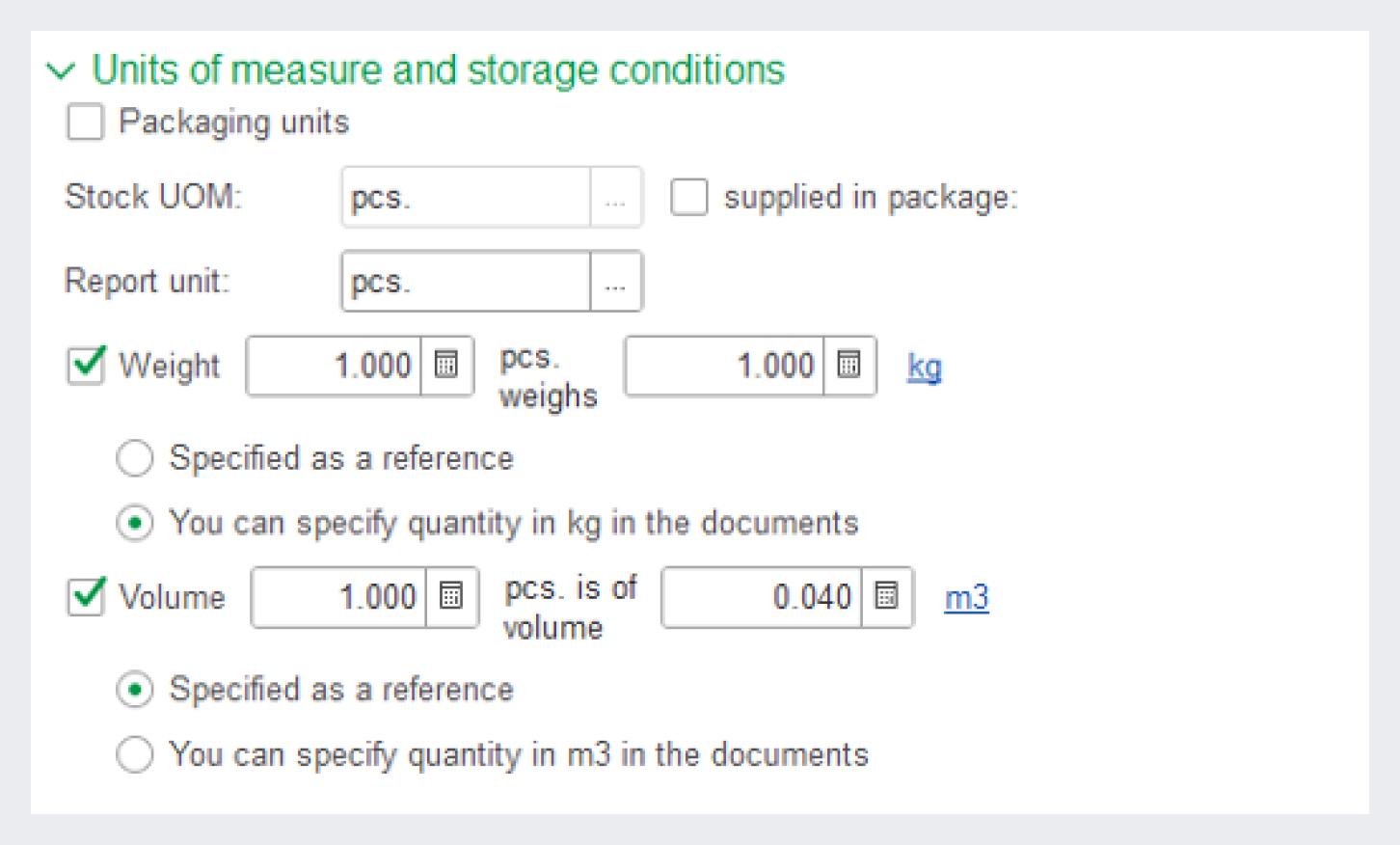

To register it in the system:

1. Create the Board 25x100x6m item for a board with a thickness of 25 mm, a width of 100 mm, and a length of 6 meters. Specify piece (board) as a stock UOM.

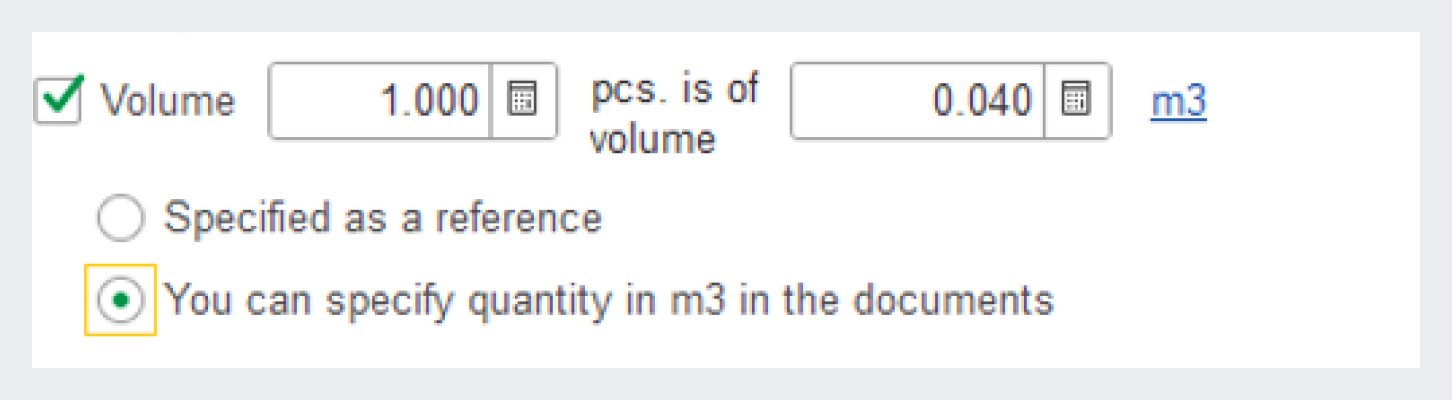

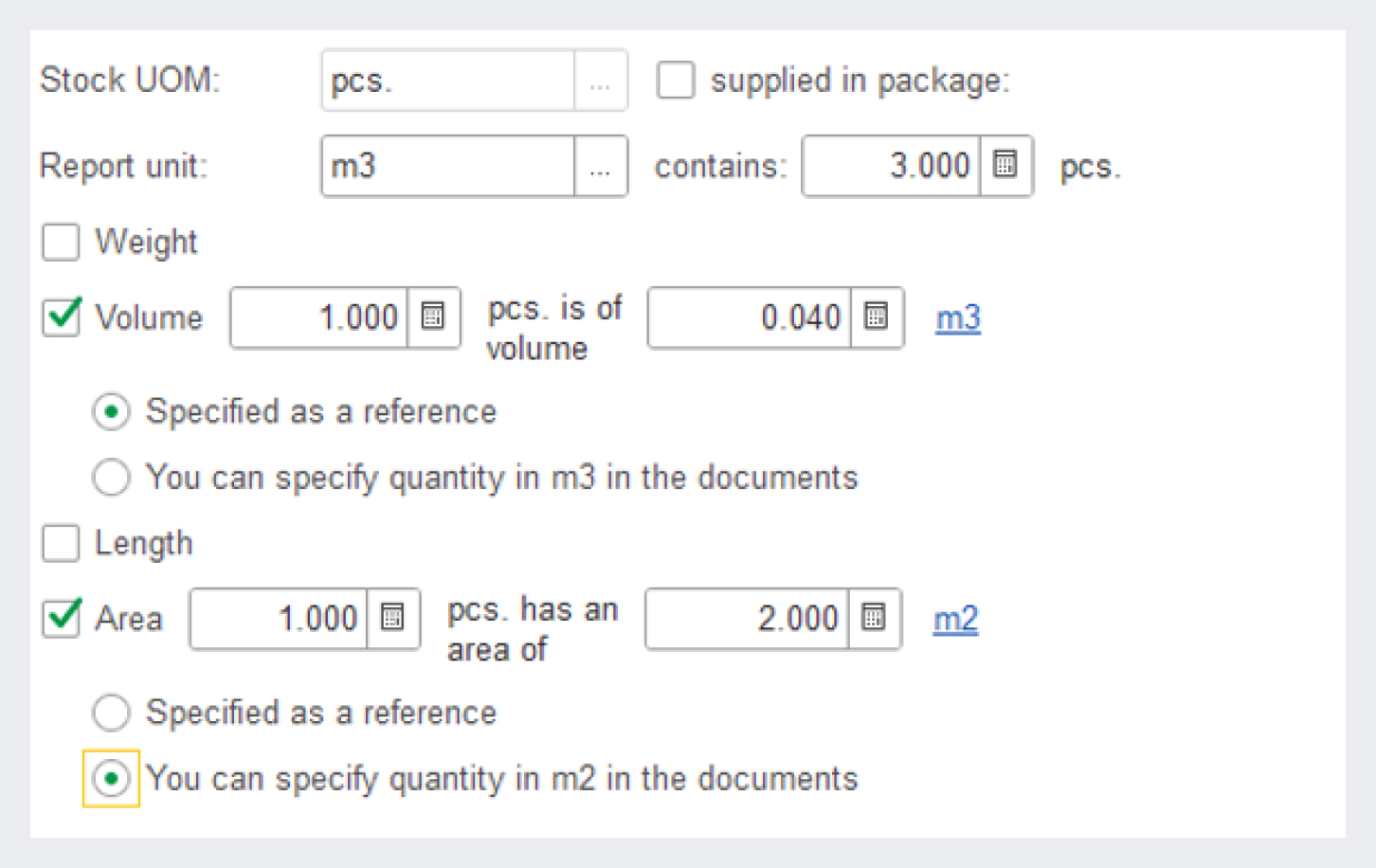

2. The volume of one board is 0.1 * 0.025 * 6 = 0.015 m3. Enable the Volume attribute in the item card as shown in the figure below:

Setting up the item volume

3. A cubic meter contains 66.667 boards (1/0.015 = 66.667), so specify m3 as a report UOM (to be able to estimate the volume of warehouse balances in m3).

4. To specify the consumption standards and actual consumption of lumber in production in meters, enable the Length attribute and specify that one board (piece) has a length of 6 meters.

Now we can specify the quantity in pieces, meters, and cubic meters in documents, taking into account the specified allowable deviation.

Let us consider one more case with a small wooden bar, for example, 1 cm thick, 1.5 cm wide, and 2 meters long. Its volume is 0.01 * 0.015 * 2 = 0.0003 m3. It seems that the number of decimal places does not fit into three digits provided in the system. However, we can overcome this restriction by setting the conversion ratio not for one bar, but for one hundred bars. One hundred bars occupy a volume of 0.03 m3, which already fits the provided number of decimal places. You can see the settings in the figure below:

Specifying the volume conversion ratio

The system will recalculate the required quantity whenever needed.

Insulation materials case

Suppose an enterprise is engaged in construction work like insulating the facades of buildings. One of the materials consumed in this production is stone wool.

Stone wool is a pressed rectangular block of material, which is placed in polyethylene packages containing several blocks in one package for easier transportation and storage.

The goods are stored in packages in the warehouse, but ordered in cubic meters (though delivered in packages by the wholesale vendors). And in production, the material is used and written off in square meters. Most often, the consumption rate of stone wool per square meter of the insulated surface is calculated, and then this value is used to calculate the required amount of materials for the entire building.

We need to:

-

Purchase goods in cubic meters.

-

Recognize goods and keep them in the warehouse in packages.

- Transfer materials to production in square meters.

As an example, let us take the Insulation of stone wool 50x600x1000 (block thickness is 50 mm, width is 60 cm, and length is 1 m). The material is supplied in packages of 8 blocks.

What we do in the system:

-

Create a new item and specify a package as a stock UOM (a piece will be a package). Why do we specify the whole package and not just one block? Warehouse keepers are unlikely to disassemble packages into separate blocks, so we do not need accounting by blocks in the warehouse. But if you need to track materials in the warehouse as separate blocks, specify a block as a stock UOM and create a package with a conversion ratio for it.

-

Enable the Volume attribute for the item. Specify the conversion ratio: one package = (0.05 * 0.6 * 1) * 8 = 0.24 m3.

- Enable the Area attribute for the item. Specify the conversion ratio: one package = (0.6 * 1) * 8 = 4.8 m2.

You can see the corresponding item card settings in the figure below:

Item volume and area

Now we can order goods from vendors in cubic meters, accept the goods to the warehouse in packaging units (pieces), and consume them in production in square meters.

Electric wires case

Another interesting case is accounting for offcuts of measured materials.

The best example is the accounting for electric wires:

-

One company produces electrical extension cords. One of the consumed materials is electric wire (Electric PVS cable 3x0.75).

-

The wire is supplied in coils that contain 500 meters of wire.

-

In the warehouse, the wire can be cut off from the coil to meet the current production needs.

-

In production, the wire is planned and consumed in meters.

-

We need to know both the total length of the wire on the balance, and in which offcuts this wire is stored: if production requires 2 meters of wire for one extension cord, two one-meter offcuts will not be enough.

Let us see how to handle it in 1C:ERP:

1. Create a new item card.

2. Specify a meter as a stock UOM. One could assume that we need to use pieces (coils) similarly to the previous examples. But the warehouse keepers can cut the cable from the coil, meaning they operate in meters. The choice of stock UOM depends on the unit warehouse keepers operate with. If the warehouse accepted and issued the entire coils, the coil would be a stock UOM. In this example, it is the meter.

3. To simplify document registration, we use the coil as a packaging unit containing 500 meters of cable.

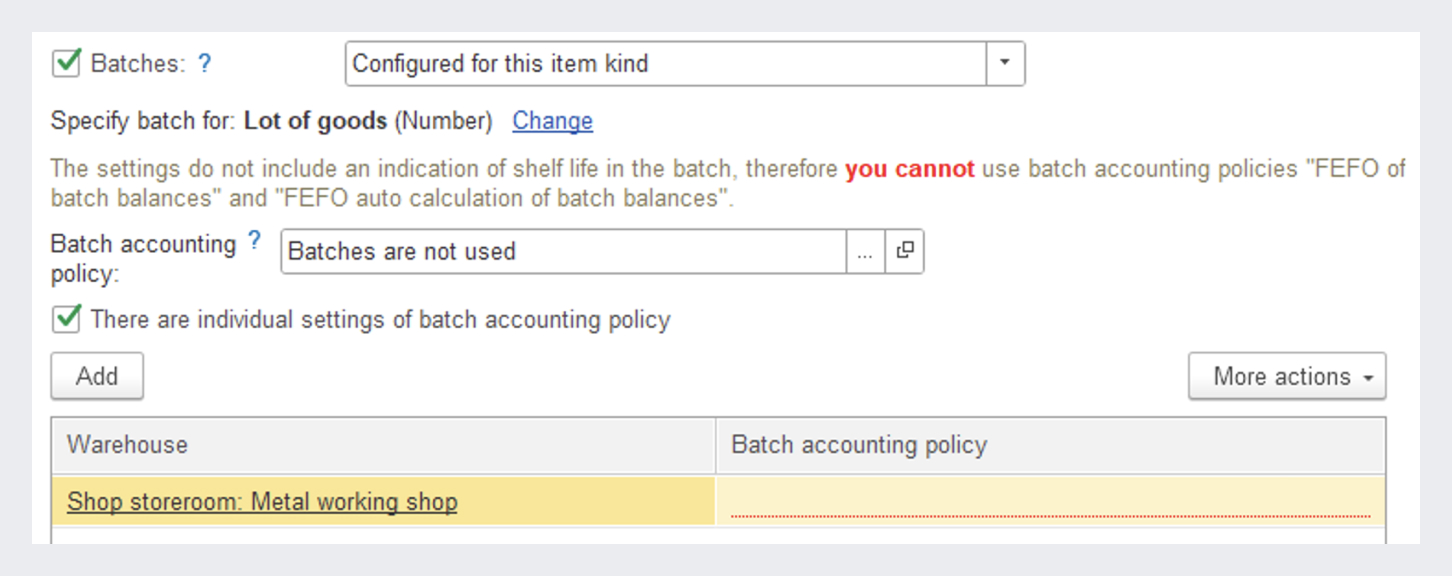

In the item kind of the new item, batches must be enabled, as shown in the figure below:

Setting up a batch accounting policy

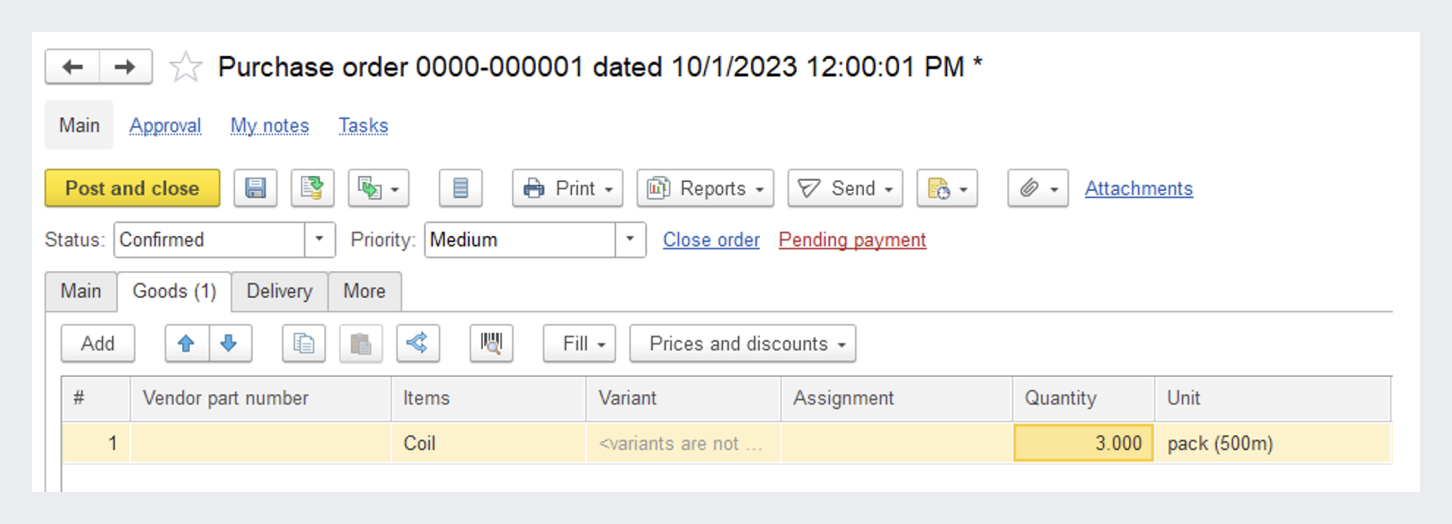

Why do we need batches? When accepting new coils from vendors, we will create a new batch for each coil. So, the length of each coil will be linked to its own batch. It will look as follows in purchase orders:

Registering a purchase order

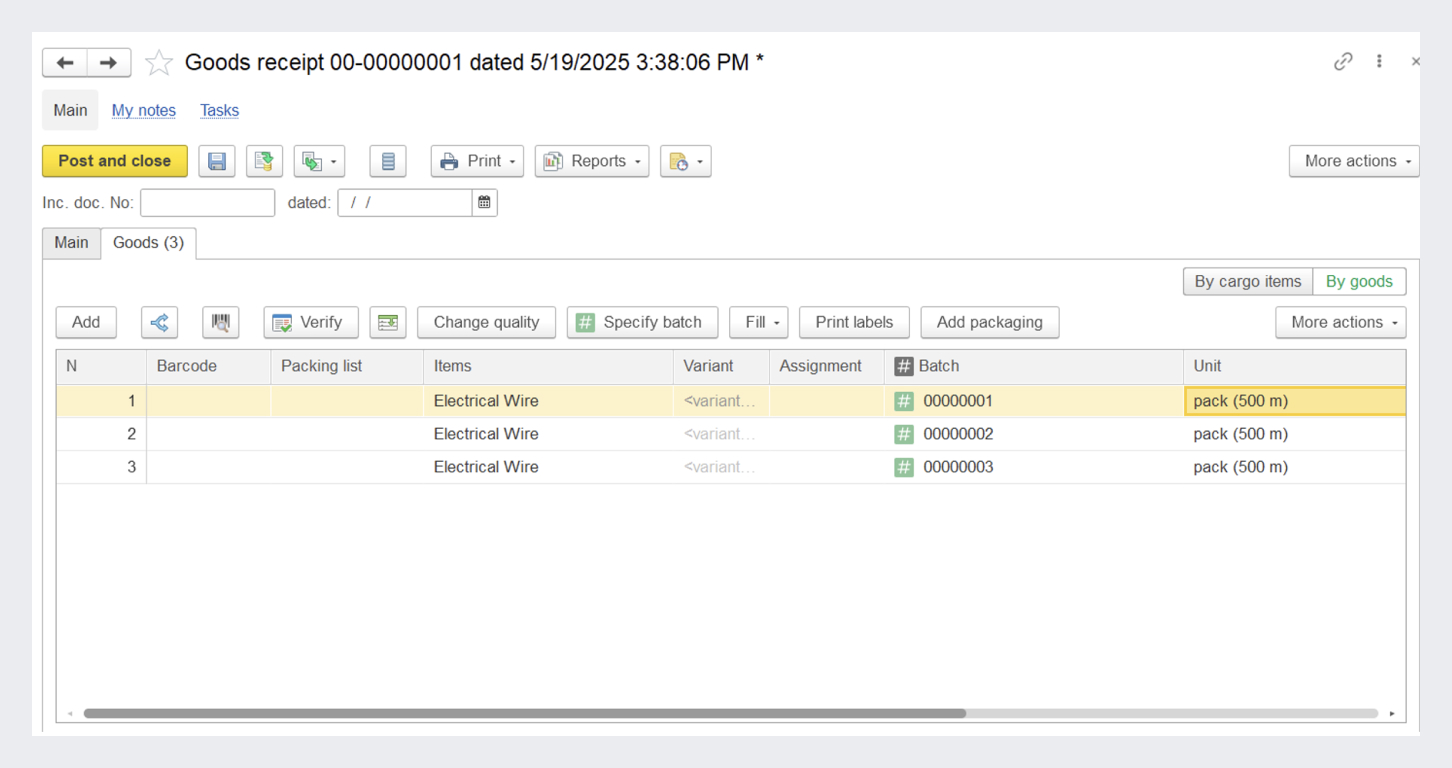

In warehouse orders:

Register a goods receipt

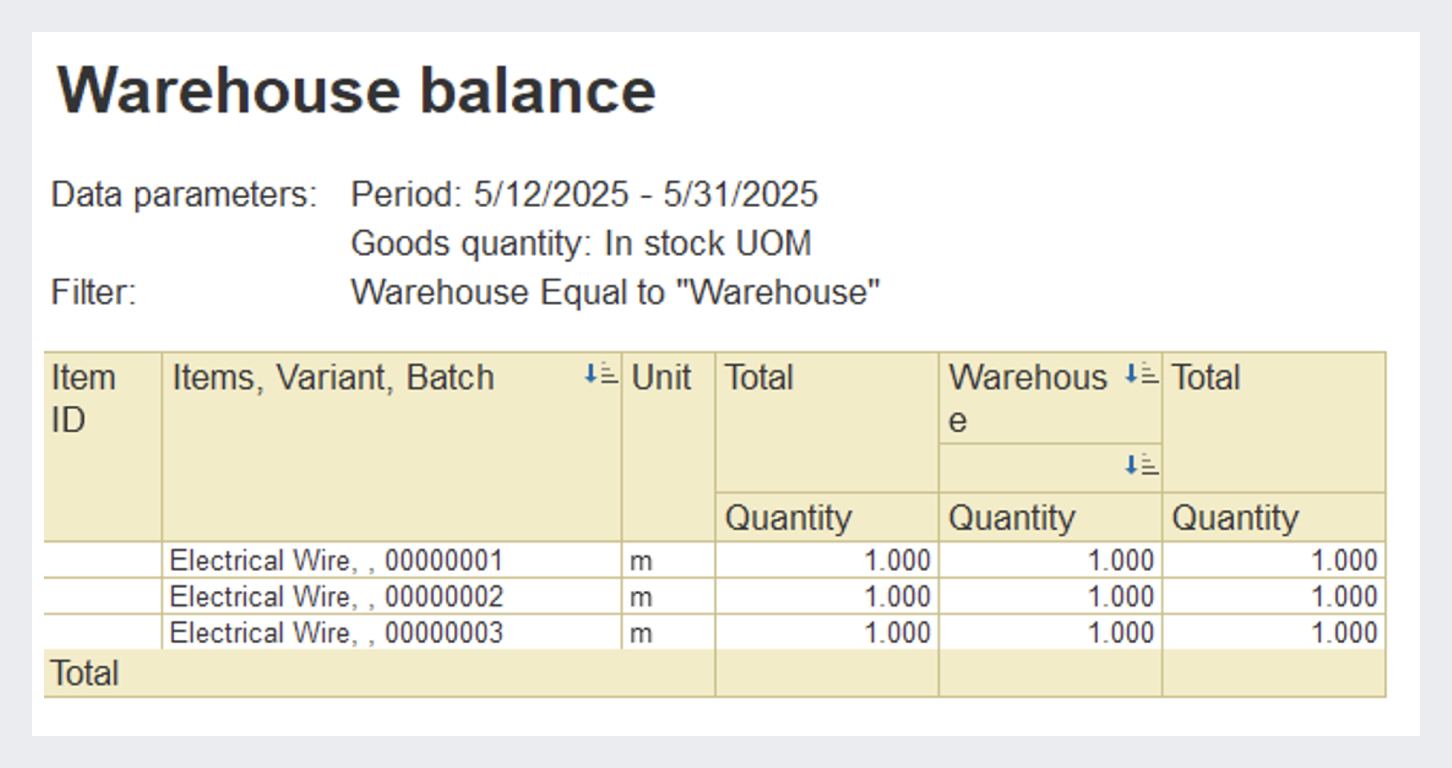

In the goods balances, it will look as follows:

Warehouse balance by coils

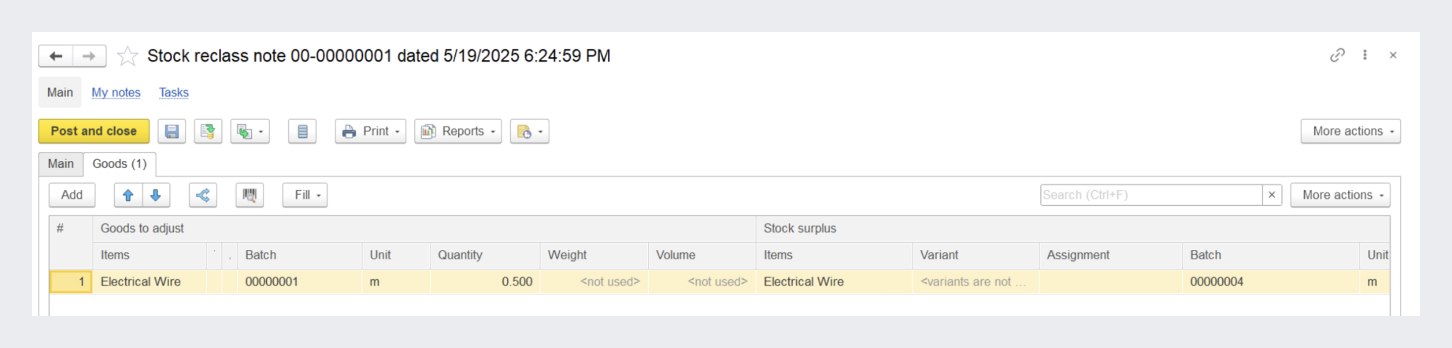

In reports, we see the total quantity of cables and their breakdown into coils. Next, we need to register cable cutting for production. To do this, we will use the Stock reclass note warehouse document, where we will write off the number of meters of cable we cut off from the original batch (coil), and pass this quantity to a new batch (a new coil received after cutting).

Cutting the wire

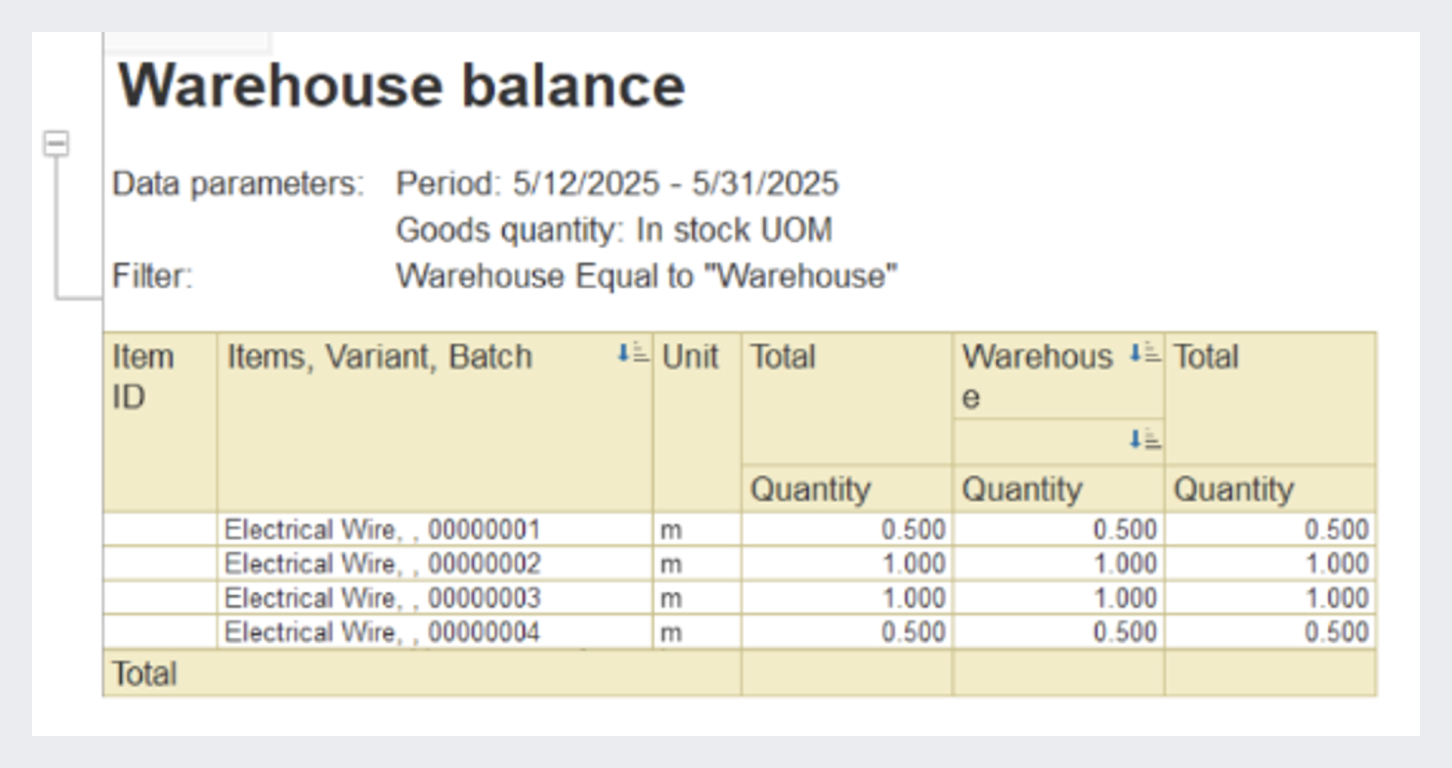

After that, we will see the following picture in goods balance reports:

Warehouse balance after cutting

We see that we have two whole coils of 500 meters and two segments of 200 and 300 meters.

Thus, the task is considered solved:

-

We can purchase and accept goods in coils.

-

We can operate with meters (cut off the goods) in the warehouse.

-

We can see the total quantity of goods in the warehouse and the quantity of goods broken down by segments.